Opening — Why this matters now

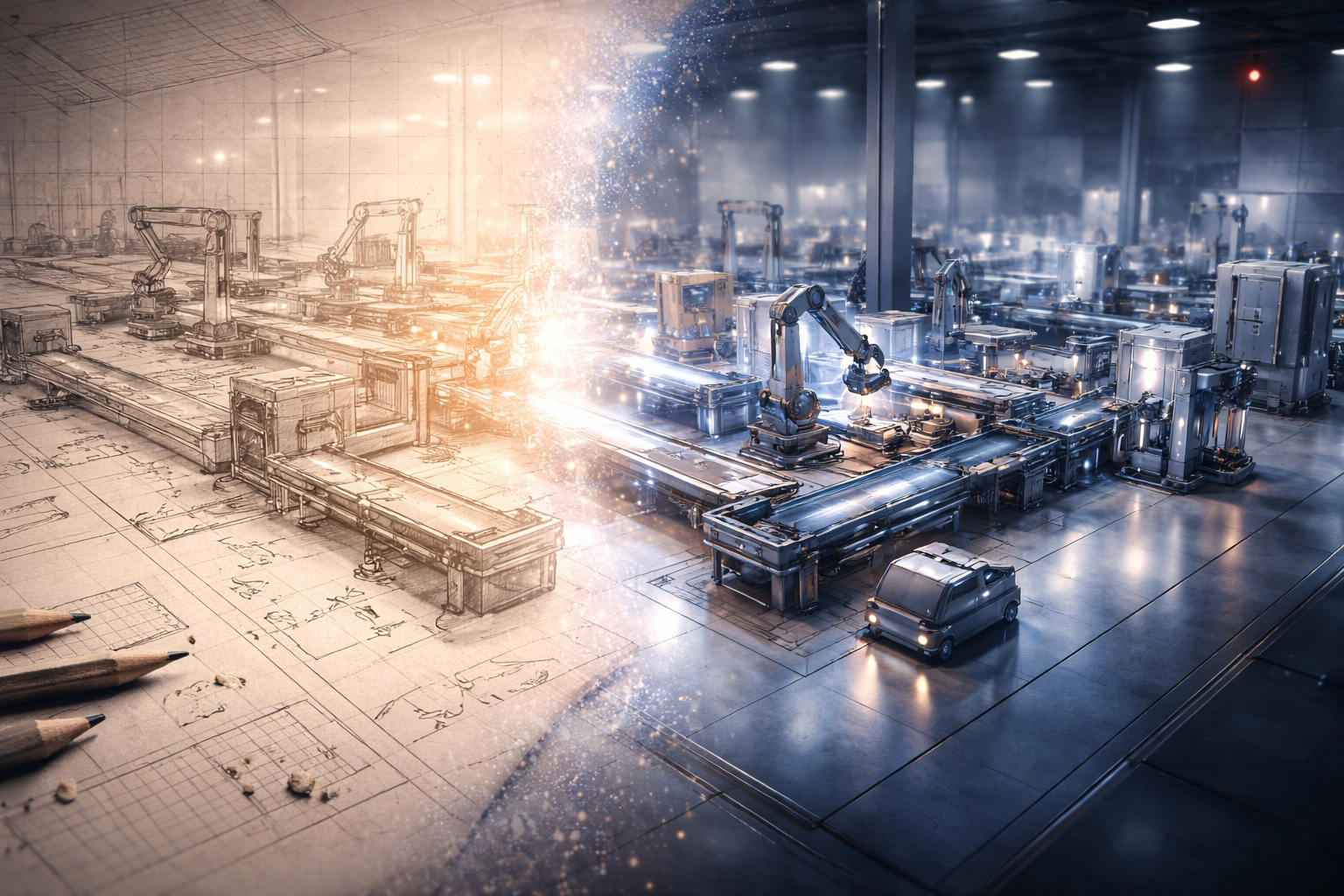

Industrial digital twins have quietly become the backbone of modern manufacturing optimization—until you try to build one. What should be a faithful virtual mirror of a factory floor too often devolves into weeks of manual object placement, parameter tuning, and brittle scripting. At a time when generative AI is promising faster, cheaper, and more adaptive systems, digital twins have remained stubbornly artisanal.

This paper asks an uncomfortable question: why are we still hand-coding factories in 2025? And more importantly, it proposes a credible alternative.

Background — Context and prior art

Digital twins are not new. FlexSim, AnyLogic, and similar platforms already power serious industrial decision-making. The bottleneck has never been simulation itself—it has been authoring. Traditional workflows require engineers to:

- Manually place objects (sources, queues, processors)

- Configure stochastic parameters (arrival rates, service times)

- Script logic in domain-specific languages like FlexScript

Large language models have shown promise in code generation, but factory layouts are spatial, not purely textual. A production line is as much geometry as grammar. Prior LLM-based approaches either ignored vision entirely or treated simulation as an afterthought.

The gap, then, is obvious: no system has reliably translated visual layouts + natural language into runnable industrial simulations.

Analysis — What the paper actually does

The authors introduce Vision-Language Simulation Models (VLSM)—a multimodal architecture that accepts:

- A layout sketch (image)

- A natural-language prompt

…and outputs executable FlexScript that runs directly inside FlexSim.

To make this possible, they build three things in parallel:

1. A real dataset (not a toy one)

The GDT-120K dataset contains over 120,000 prompt–sketch–code triplets, derived from realistic factory investigations across:

- Multiple layout types (linear, U-shaped, conveyor)

- Levels of automation (manual → AGV → robots)

- 13 distinct industries

Each sample includes statistically validated arrival and service-time distributions—meaning the code is not only syntactically correct, but industrially plausible.

2. A multimodal architecture that stays lightweight

Rather than chasing ever-larger models, the paper emphasizes deployability:

| Component | Design Choice | Rationale |

|---|---|---|

| LLM backbone | StarCoder2-7B / TinyLLaMA-1.1B | Strong code priors, manageable cost |

| Vision encoder | OpenCLIP | Robust spatial grounding |

| Fusion module | Linear / 2-layer MLP | Low latency, stable training |

The result is a system that SMEs could plausibly run on-prem—an underappreciated but critical design constraint.

3. Metrics that actually reflect reality

Text similarity metrics like BLEU are nearly useless for simulation code. Instead, the authors introduce:

| Metric | What it measures | Why it matters |

|---|---|---|

| SVR | Structural Validity Rate | Is the topology correct? |

| PMR | Parameter Match Rate | Are distributions and values faithful? |

| ESR | Execution Success Rate | Does it actually run? |

Execution, notably, is treated as a first-class metric. As it should be.

Findings — What the results show

The experimental results are unambiguous:

- Code-pretrained models outperform larger general LLMs

- Vision grounding significantly improves execution robustness

- Small models, when retrained properly, can be competitive

A representative comparison:

| Model | SVR | PMR | ESR |

|---|---|---|---|

| LLaMA3-8B | ❌ | ❌ | ❌ |

| TinyLLaMA-1.1B | High | High | Moderate |

| StarCoder2-7B + vision | ~Perfect | ~Perfect | Highest |

Qualitative examples reinforce the numbers: weaker models produce plausible-looking but structurally broken layouts; VLSM reproduces correct object ordering, routing, and execution flow.

Implications — Why businesses should care

This work quietly reframes digital twins from engineering artifacts into generative assets.

For industry, this means:

- Faster iteration cycles for factory design

- Lower dependency on scarce simulation specialists

- A path toward conversational, sketch-driven simulation authoring

For AI practitioners, it delivers a broader lesson: multimodal grounding matters most when correctness has consequences. Industrial systems do not forgive hallucinations.

The more subtle implication is strategic. By formalizing execution as an evaluation primitive, the paper nudges the field away from pretty demos and toward operational reliability—a necessary shift as AI enters physical and economic systems.

Conclusion — The quiet arrival of runnable AI

Generative Digital Twins are not flashy. They do not chat. They do not role-play. They run.

By unifying vision, language, and executable logic, this work shows how AI can move from describing systems to instantiating them. Not in theory, but in production-grade simulation environments.

That is not hype. It is infrastructure.

Cognaptus: Automate the Present, Incubate the Future.